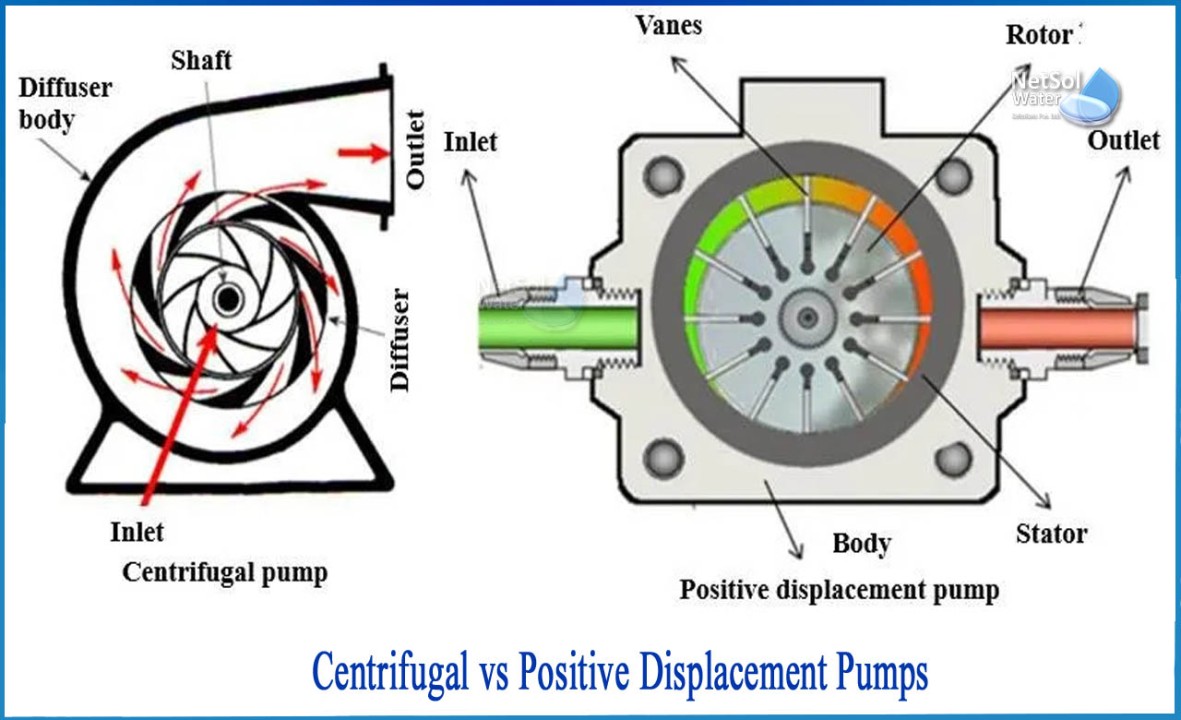

A Centrifugal Water Pump versus a Positive Displacement Water Pump

Positive displacement (PD) and centrifugal water pumps are very powerful tools, which move water through complex municipal and industrial systems. However, it is vital to click here to choose the right one for the needs of your facility.

Centrifugal Water Pumps

These are some of the most commonly used water pumps globally. Because they are made for low-viscosity liquids that tolerate a high flow rate without the risks of any degradation, these water pumps are suitable for moving water. They depend on the changing flow and often transfer kinetic force from the motor to the water by spinning their impellers.

When to Use Centrifugal Water Pumps

We commonly use centrifugal pumps to transfer water at a high flow rate. It is mostly used when pumps are needed to carry a large volume of water, making it ideal in various applications, like the following:

- Shipbuilding and marine – For firefighting, cooling systems, and ballast control, you will need a centrifugal pump because of its capability to move a large volume of water.

- Irrigation and agriculture – These pumps are extensively used for irrigation, allowing farmers to distribute water from water containers or tanks to their farms.

- Water distribution and treatment – Centrifugal pumps are important in many water treatment facilities that move water through a filtration system. Municipal systems also depend on these pumps to distribute water, thanks to their capability of efficiently handling a large volume of liquids.

- Power generation – You can use the pumps for cooling systems, condensate extraction, and boiler feed water, among other uses.

Pros

- Idea for low-medium viscosity liquids – These pumps are suitable for dealing with low-medium viscosity liquids, like water.

- Low maintenance and simple design – They come with simple designs with a few moving parts; thus, minimizing the associated costs and requirements for maintenance.

- High flow rates – A centrifugal water pump is good at delivering fluids at a high flow rate, making it suitable for applications where carrying a large volume of liquid is necessary.

Cons

- Not suitable for viscous liquids – A centrifugal water pump is less efficient when it comes to handling viscous liquids because the design of its impeller is less effective.

- Inconsistent water flow at different pressures – The rate flow of the pump depends on the equipment’s pressure, resulting in output fluctuations when there is a change in pressure.

Positive Displacement Pumps

Positive displacement (PD) pumps move water by enclosing a fixed amount of fluid repeatedly and carrying it mechanically in the system. The action of the pump is cyclic and components, like vanes, diaphragms, rollers, gears, screws, and pistons, help the entire system to move water. They have the capability of producing a consistent rate of water flow. The rate of these pumps remains the same even when there is a change in pressure. PD pumps often work using a vacuum generated through the water insertion. Once the chamber is filled with water, the pumps rotates, thereby increasing the pressure. Then, the water passes through the discharge pipe’s port.

When to Use a PD Pump

Some people prefer using a PD pump because of its capability to handle fluids with high viscosity at high pressure. Although centrifugal pumps are the most common pumps used because of their simplicity, a PD pump is a solution that handles more complex conditions where a centrifugal pump can’t, thanks to its capability of running at any curve point. This makes them ideal for the following applications:

- Mining – In this industry, a PD pump is used to dose liquids used in the processing of materials and pump slurries with very solid content.

- Maritime – In dockyards and on ships, this pump is ideal for reliably and efficiently managing waste, bilge pumping, and fuel transfer.

- Agriculture – A PD is used for precise pesticide application, fertigation, and irrigation, ensuring the required liquid amount is delivered when it’s required.

- Wastewater treatment – A positive displacement pump is used to handle sludge and other applications where solid content and varying viscosity are common.

Pros

- Self-priming – A PD pump can prime itself – meaning it can draw liquids from water containers or tanks without any external support, making it helpful in a scenario with intermittent flow of fluid.

- Ideal for viscous liquids – The pumps excel well at dealing with viscous and thick liquids, including syrups, oils, and slurries, making them suitable for industries, such as petrochemicals, pharmaceuticals, and food processing.

- Consistent pressure and flow – A PD pump provides a continuous or steady flow rate and it doesn’t depend on the equipment’s pressure changes. This makes it dependable for applications where stable outputs are required.

Cons

- Sensitivity to change in pressure – A positive displacement pump might be very sensitive to the system’s pressure changes, causing inefficiencies or damage if not managed properly.

- Limited flow rate – A positive displacement pump can have a limitation in a high flow rate application because its output is constant and fixed.

Key Differences

There are several differences of centrifugal and positive displacement water pumps. Some of these key differences are in terms of the following:

1. Mechanics

The key difference between the two is seen in their mechanics as well as how they work. Centrifugal pumps often transmit velocity to the water, creating pressure, while PD pumps trap a particular water amount in the system and transfer it to a discharge port.

2. Performance

The flow rate in centrifugal systems change when the pressure changes. On the other hand, the flow rate in PD systems remain the same even when there is a change in pressure.

Before you buy any system for your needs, consider the working conditions. For instance, if you are planning to deal with liquids that has low viscosity and pressure, then you might want to invest in a centrifugal pump. However, you plan to operate in areas with wastewater, experts recommend that you go for a PD pump. Do you know why? The answer is simple – PD pumps handle liquids with high viscosity and the flow rate remains the same even when there is a change in the liquid pressure.